Case Study: Organ Manufacturing

Case Study: Organ Manufacturing

The Futrfab environment offers a unique solution for control of the environment of 3D printing equipment including environmental conditions such as humidity and temperature. The Futrfab environment offers a unique solution for control of the environment of 3D printing equipment including environmental conditions such as humidity and temperature.

Production of human organs by three dimensional printing technology will require intricately controlled environments that are clean and sterile — as well as easily sterilized after use. A Futrfab offers a unique solution for control of the environment required by 3D printing equipment.

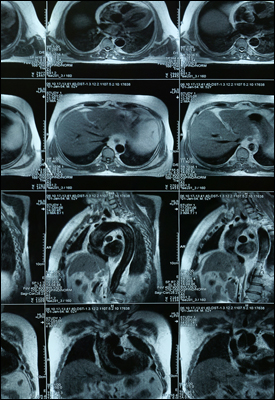

To enable the highly demanding printing process, muscle, nerve, fat cells, vascular systems and the like need to be placed with accuracy in a three dimensional model. By studying a patient before fabricating a unique organ product, cognitive computing and medical imaging technologies may be combined with Futrfab’s patented technology to create these models and organs.

|

In the future, manufacturing replacement organs for patients will be commonplace. The Futrfab environment creates the perfect platform for pioneering R&D in this field today.

|